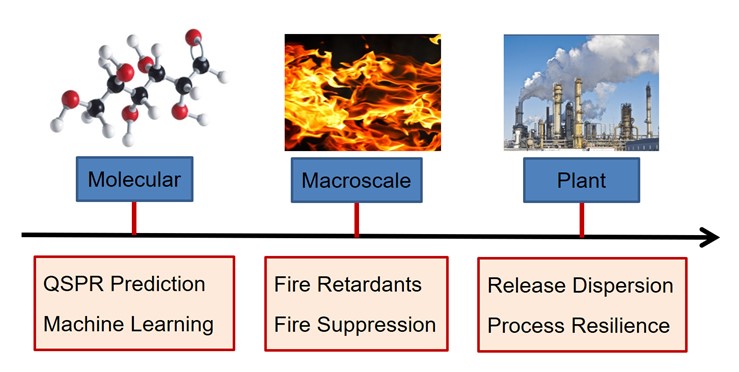

Our research is highly multidisciplinary in the process safety area with intent to resolve the most critical safety/sustainability problem in the industries, which is to prevent and mitigate hazardous phenomena including fire, explosion, and toxic release, from a molecular level, macroscale, to a plant level, as well as to address global challenges in carbon capture and wastewater treatment. We collaborate extensively with research groups in Chemical Engineering, Chemistry, Materials Science and Engineering, Computer Science, and Mechanical Engineering.

Major Research Area

Area 1 Flame Retardant

- Bio-derived flame retardant

- Self-extinguishing plastics

- Fire resistant coating (pipeline corrosion)

- Multifunctional wood composites

Area 2 Composite Manufacturing

- Sustainable manufacturing at large-scale

- Mixed matrix membrane (MMM)

- Carbon capture and utilization

- Wastewater treatment

Area 3 Machine Learning

- PSM: process incident prediction and prevention

- Materials property prediction and consequence prediction

- CO2 adsorption and process optimization

- Pipeline failure modeling and prediction

Area 4 Fire and Explosion Dynamics

- Large-scale LNG fire and explosion testing

- Large-scale fire whirl testing

- CFD modeling of CO2 flow, release and dispersion

- Hydrogen fire and explosion safety

Major Research Equipment

- Process 11 Parallel Twin-Screw Extruder by Thermo Fisher Scientific

- Cone Calorimeter by Fire Testing Technology (FTT)

- Oxygen Index by Fire Testing Technology (FTT)

- FAA Micro Combustion Calorimeter by Fire Testing Technology (FTT)

- UL 94 Flame Chamber by Fire Testing Technology (FTT)

- RC1 Reaction Calorimeter with FTIR by Mettler Toledo

- Spin Coater

- Spinning Drop Tensiometer

- Microscope

- Focused Microwave System

- Autoclave for Hydrothermal Synthesis

- Bench Top Hot Press

- Vacuum Oven, Precision Oven, Isotemp Oven

- Rotary Evaporator, Freeze Dryer